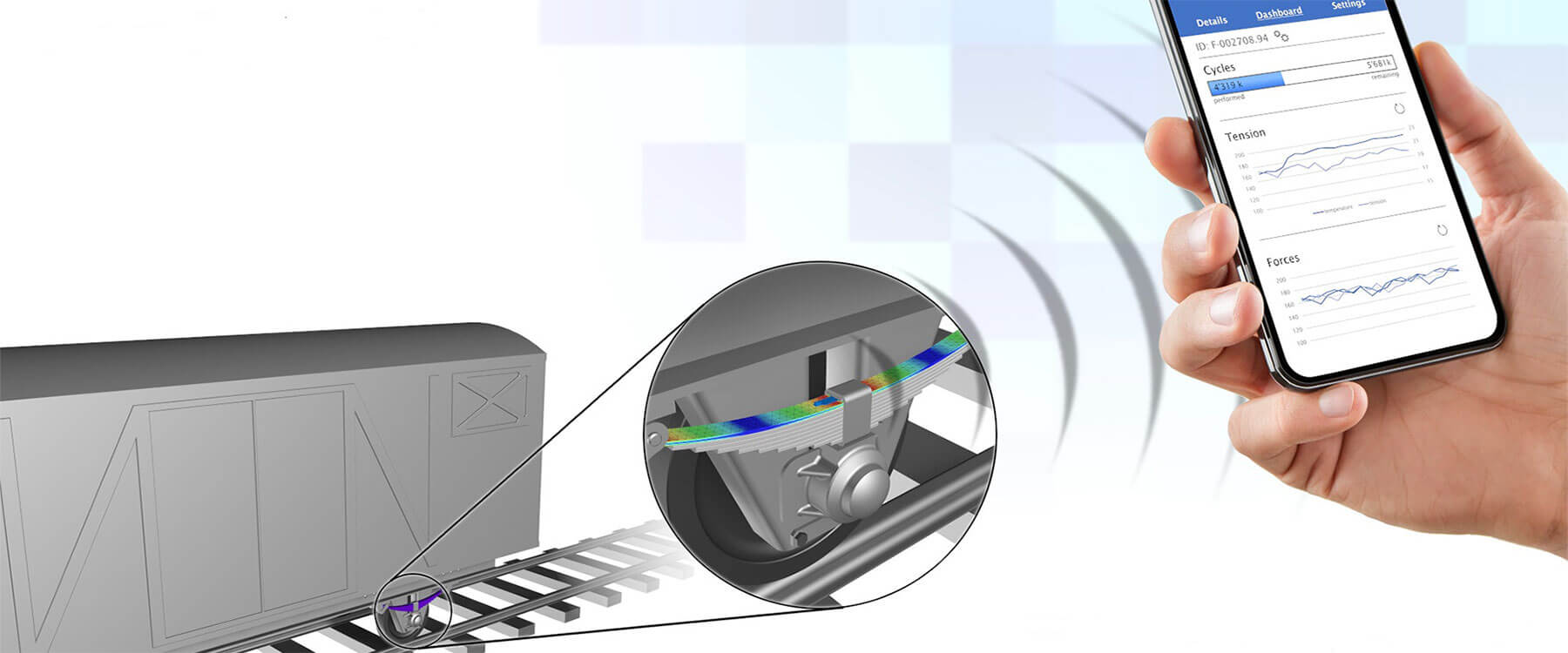

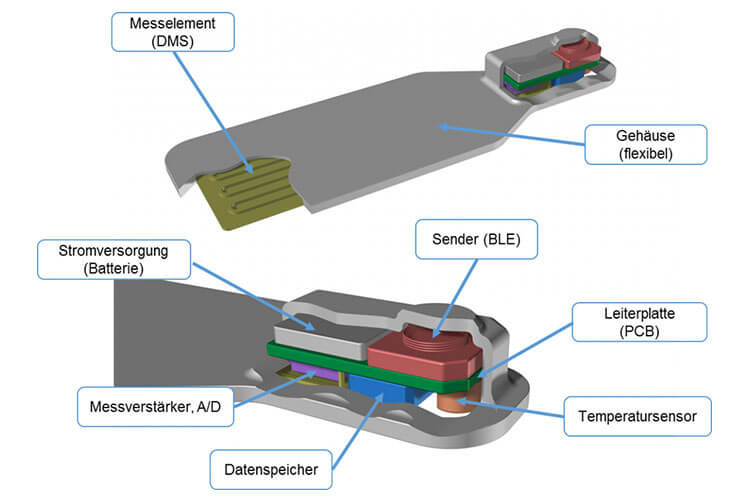

A unique and award-winning new development from Federnfabrik Schmid AG bridges the gap between a conventional mechanical spring and the digital age. An innovative sensor monitors the spring and can transmit all important data via a radio interface to assess its current actual condition, which can be evaluated online using special software.

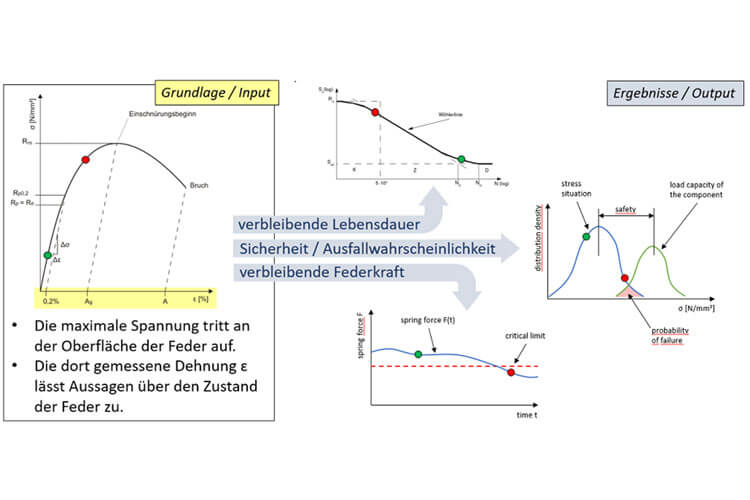

Technical springs are used in industry in a wide variety of applications. Many applications have one thing in common: the real stresses on the spring in operation are usually not known precisely enough to make a reliable statement about its condition. The design of springs is often based on theoretical assumptions and models, e.g. to determine the stress relief or the service life. These theoretical assumptions are the result of various tests under laboratory conditions and cannot always be transferred 1:1 to the specific application.

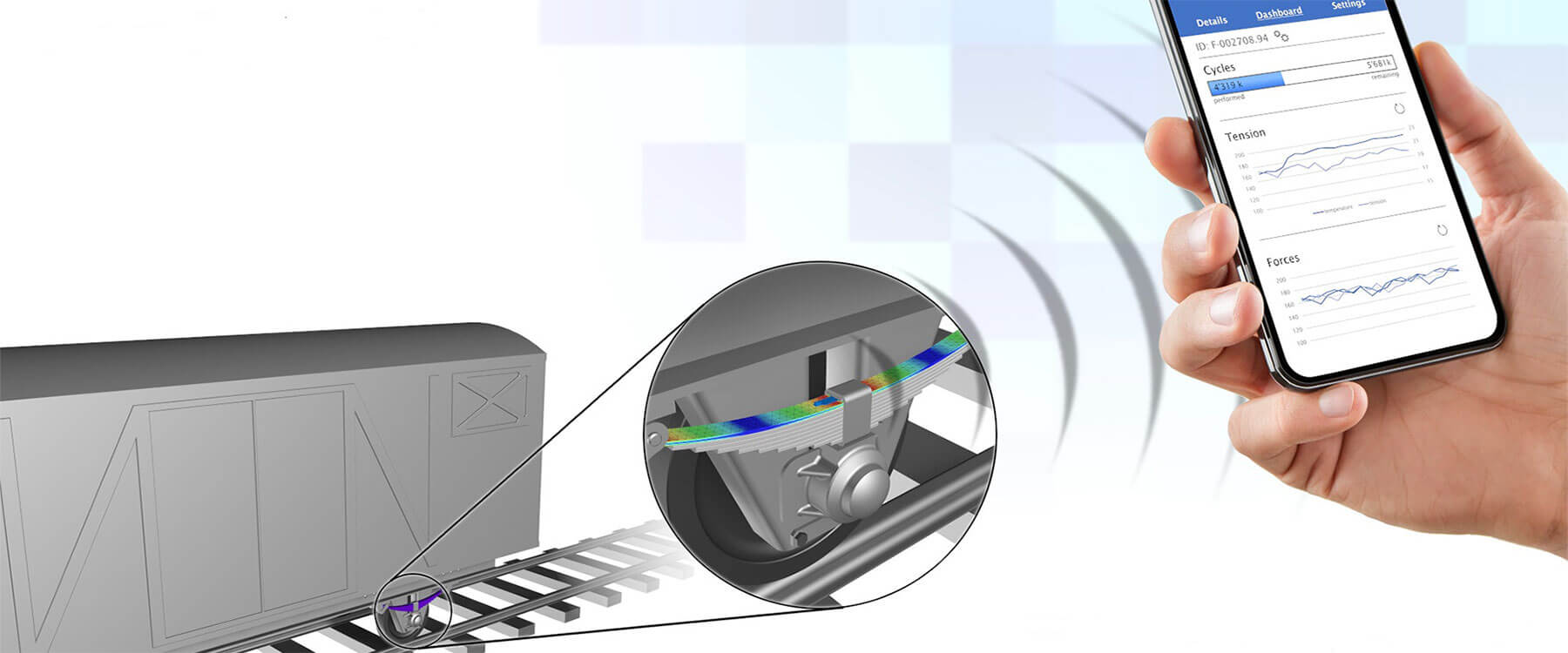

The intelligent sensor is usually composed of the following components:

Monitoring module, consisting of a strain gauge to determine the deformations and thus the stresses on the surface, a temperature sensor, an acceleration sensor, a memory module that temporarily stores the acquired data and an output module that transmits the stored data via a suitable interface (Bluetooth).

Added to this is the software, which processes the data obtained in this way in a suitable form and displays the desired information on a display device (e.g. smartphone). Through clever networking, it is possible to make the status of an i-Spring® visible from anywhere in the world.

With the data obtained, in addition to an online display of the data, various key figures can be determined via the software, such as the remaining service life until theoretical failure in a dynamic application, the failure probability of a spring in relation to its force absorption capacity, and the remaining spring force below the critical limit.

This solution opens up many new possibilities for the spring.

Development of a sensor that monitors the spring at the point of use, can transmit collected data wirelessly and enables a statement to be made about its condition via an evaluation tool.

The intelligent sensor can measure all relevant variables, store them temporarily and transmit them to an evaluation tool via an interface.

The recorded data is processed according to customer requirements and used to detect critical component conditions and prevent application failure.